About us

We are a team of entrepreneurs pushing maritime innovation and foil technology under the FLY 4 ALL SA holding.

Under the same umbrella, we develop the brand TAAROA Hydrofoil in order to bring our innovative concepts to the water sports market.

We are based in Lausanne, Switzerland, and we have sales offices in San Francisco, CA and Biarritz, France.

Our focus centers on maritime mobility and hydrofoil technology.

By using our experience in autonomous systems, we are developing increasingly more efficient hydrofoils, and creating innovative technology mixing hardware and software for the maritime industry.

Pushing the limits of maritime mobility.

TAAROA Hydrofoil has a clear objective: to break new dimensions in water sports by offering modular and technological products at a competitive price. We focus on quality, performance, and durability when designing our hydrofoils, specifically targeting the wing, surf, wind and kite foiling markets.

We design the next generation of surfing hydrofoils.

We start where conventional methods end.

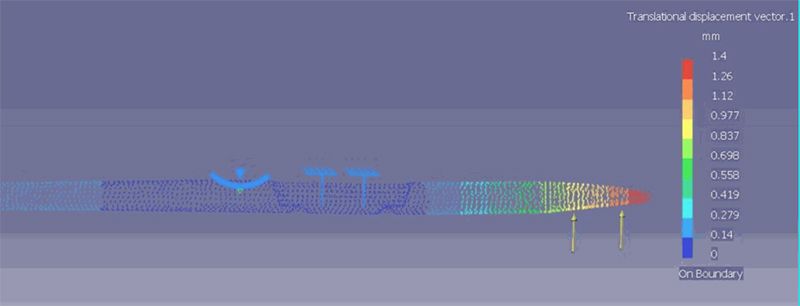

We use the latest technology inherited from the aerospace and automotive industries, including c

omputational modeling and data analysis to enable the future of foiling.

Many compare the sensation of foiling with flying. Who doesn’t dream of flying?

01

Production

Our factory is equipped for serial production of advanced composite parts. This process incorporates an atmosphere controlled room, vacuum pumps, and injection machinery for scalable production.

02

Innovation

We use unique techniques inherited from the automotive and aerospace industries, now applied to the maritime world. These techniques help us produce lightweight materials that are as strong as steel with the best quality to cost ratio.

03

Process

Our highly skilled technicians and engineers are trained using established operational procedures and benefit from a strict internal auditing system to ensure quality control, safety, and environmental care .

04

Quality

Every step of our internal production process is optimized for continually improving repeatability, e fficiency and management of non-conformities.